Sustainability in production

Click through the graphic to find out where sustainability aspects play a role at a Fresenius Kabi production site – here in the manufacturing of infusion solutions.

Emissions in the upstream and downstream value chain – Scope 3

Emissions in the upstream and downstream value chain – Scope 3

We need raw materials and preliminary products to manufacture our products, such as nutritional supplements, infusion solutions, infusion bags and drugs. The finished products are in turn supplied to pharmacies, hospitals and health centers and ultimately to patients via distributors. All these steps generate greenhouse gas emissions, known as Scope 3 emissions.

Fresenius Group's climate targets and Scope 3 emissions Climate protection at Fresenius KabiHuman rights

Human rights

Our commitment to respecting human rights also extends beyond our own corporate activities and our core business. For example, we source raw materials and intermediate products for production from other Kabi sites as well as from external suppliers. In line with our human rights program, we take human rights concerns into account when selecting and working with our suppliers and business partners.

Further informationProduct development

Product development

The further or new development of products and processes is an integral part of our strategy. Developments take place at various levels. For example, we launched a vegan version of our Fresubin nutrition drink. In the area of biosimilars, we are dedicated to the development of cost-effective drugs based on reference products.

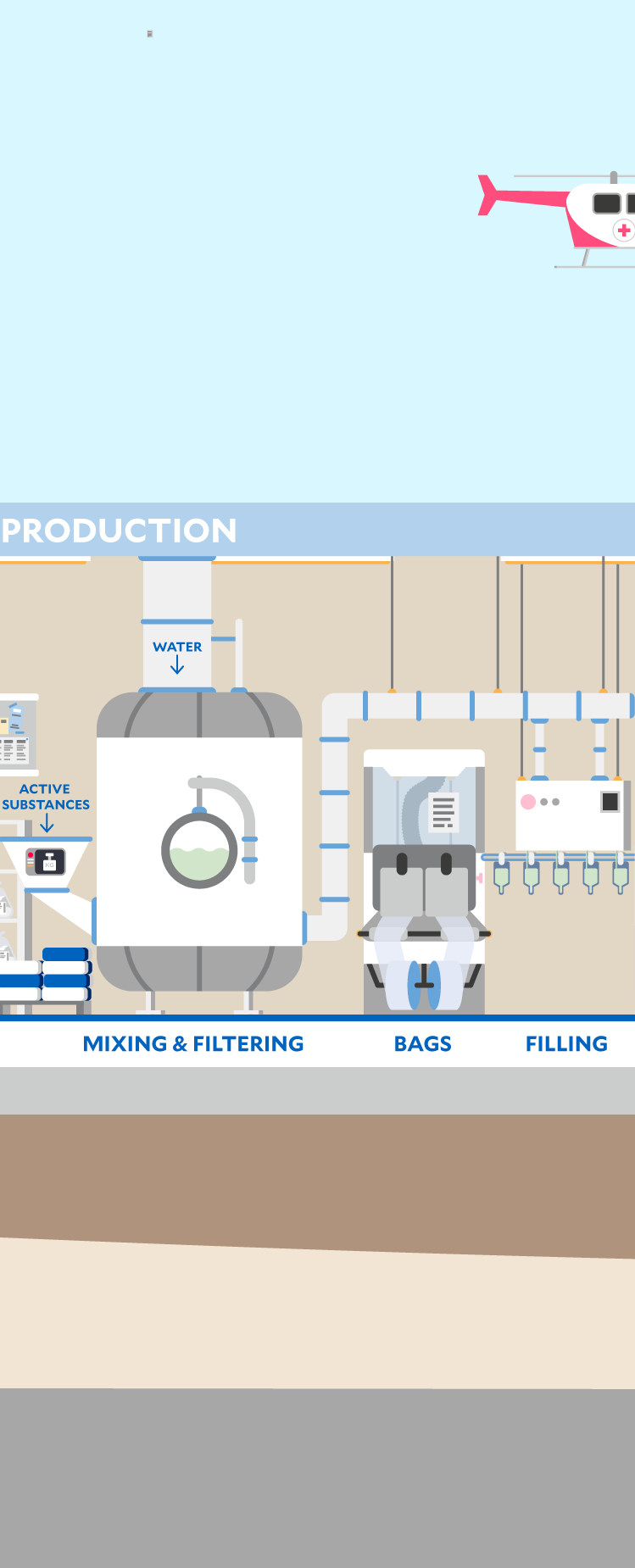

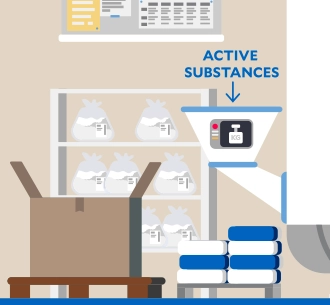

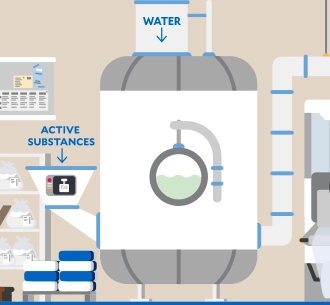

Further informationWater and waste water

Water and waste water

Water is a valuable resource. To ensure the quality of our products, we depend on the availability of water. At the same time, we are responsible for the proper handling of waste water from production.

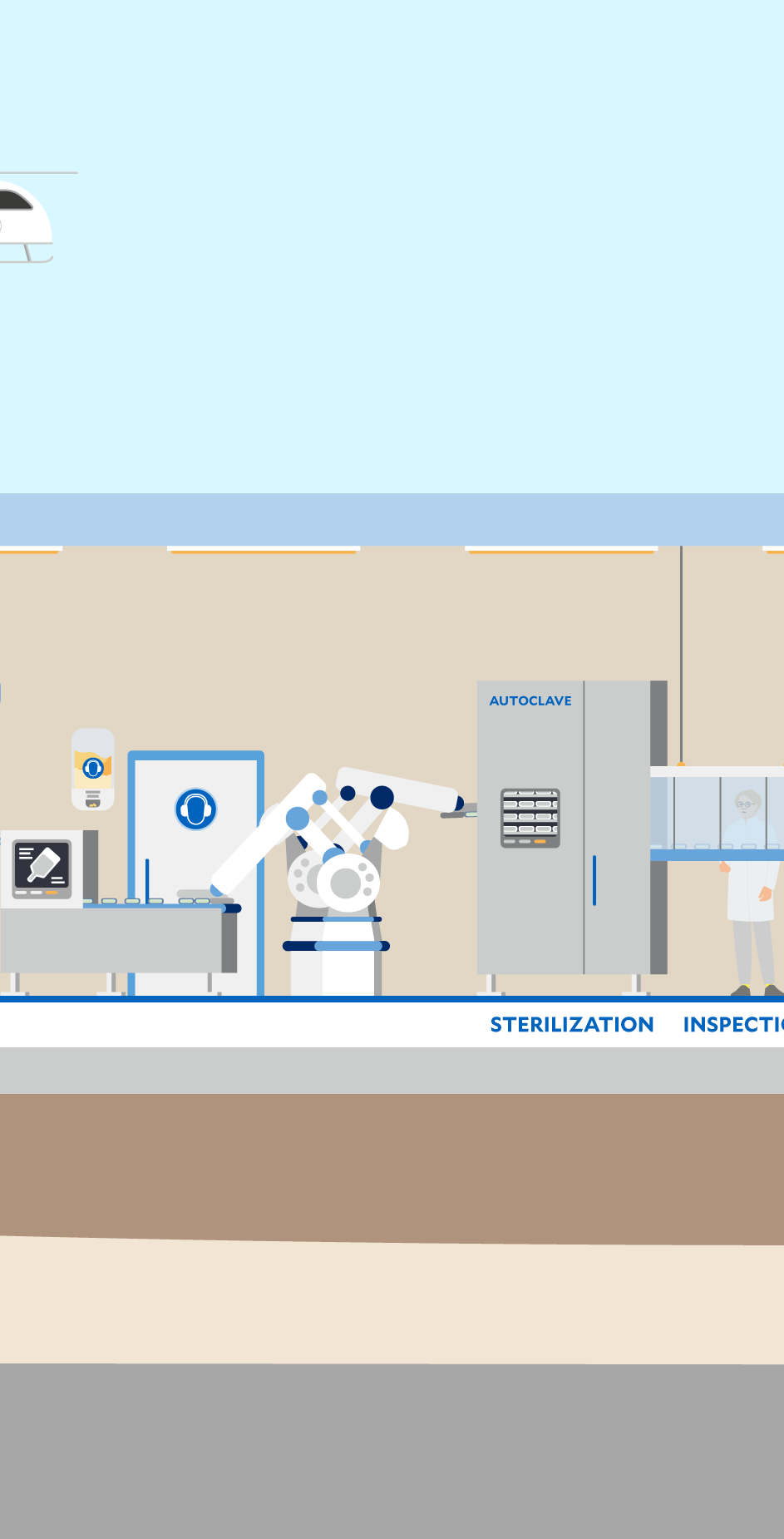

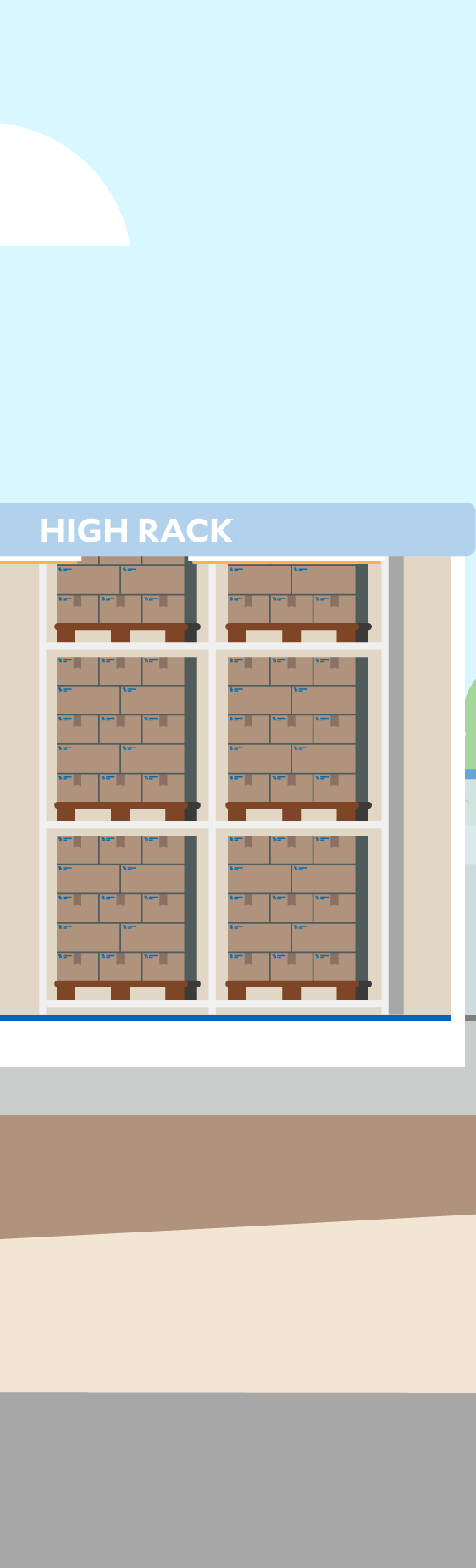

Further informationAutomation and digitalization

Automation and digitalization

We use automated and digitalized solutions to make work processes more efficient and product applications safer. In production, for example, sections such as filling, sterilization, and packaging are completely automated.

Further informationEnergy and climate

Energy and climate

High-energy processes are used at our production sites, such as the sterilization of infusion solutions in an autoclave. In order to reduce the greenhouse gas emissions released by these processes as far as possible, we are gradually driving forward energy efficiency measures as well as the use of renewable energy and the expansion of large photovoltaic systems.

Further information Highlight story: Global Competence ClusterQuality of the products

Quality of the products

Patient safety and therefore product quality are our top priority. Structured processes, training and comprehensive quality management are fundamental to this. Regular checks are carried out at our sites to ensure that all relevant standards and regulations are complied with.

Further informationWaste management

Waste management

Waste is mainly generated as by-products of production processes or as packaging material in the downstream value chain. Strict legal regulations also dominate the handling of these raw materials.

Further informationWorking conditions and occupational safety

Working conditions and occupational safety

We want to offer our employees at our production sites and in our administrative units a safe and healthy working environment. We support them in their personal development with appropriate programs through a culture of learning.

Further information Highlight story: OHS recognition HainaAccess to healthcare

Access to healthcare

We see the development of products as our task that helps to promote medical progress in acute and follow-up care and improve the quality of life of patients. At the same time, we want our products to enable more and more people around the world to have access to high-quality and modern therapies.

Further information Highlight story: Angels for Change